Safety

- Increase switchgear safety and reliability, prevent damage while operation.

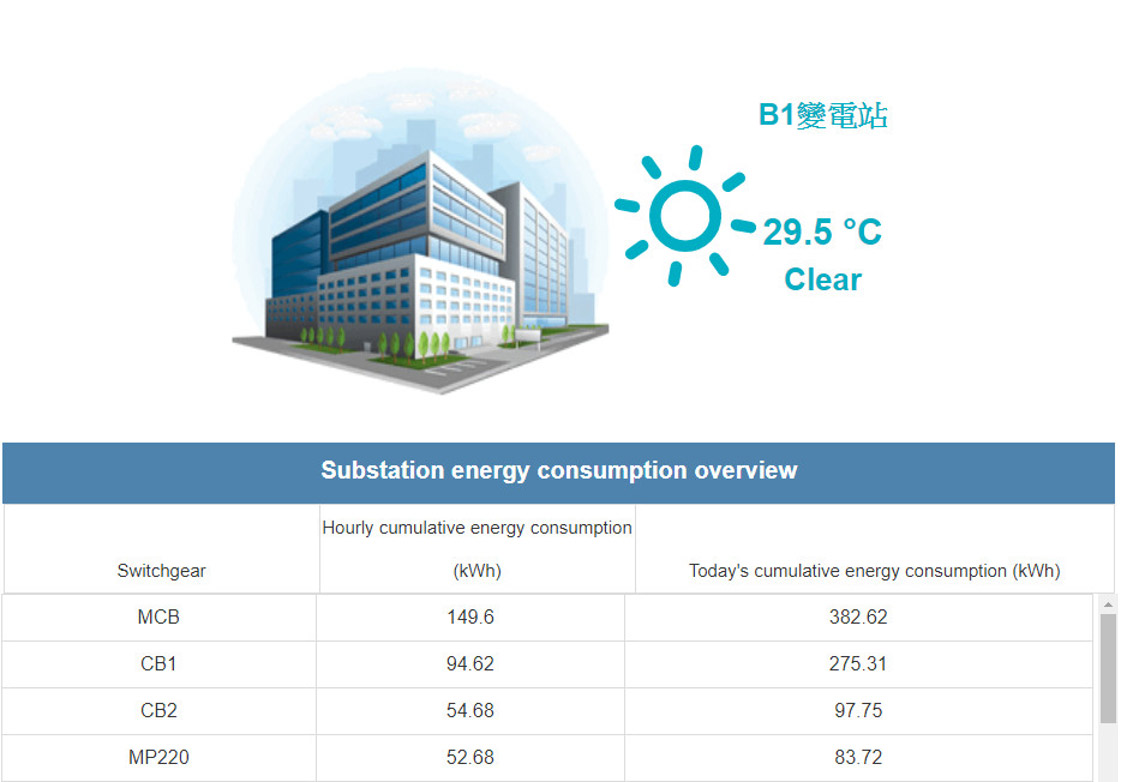

Cost

- Reduce or without labor force to monitor for switchgear in substation, greatly decreasing enterprise cost.

Efficiency

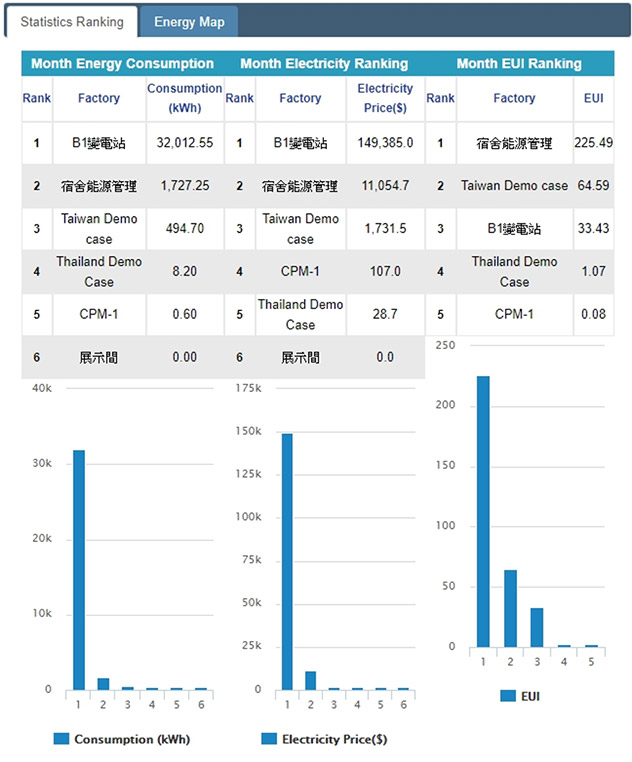

- Consolidated statistic function on power consumption and electricity cost enhances the efficiency of electricity management.

Alarm

- Potential switchgear accident warning.

Message

- Abnormal info. notification shorten the duration of troubleshooting and power outage.

Analysis

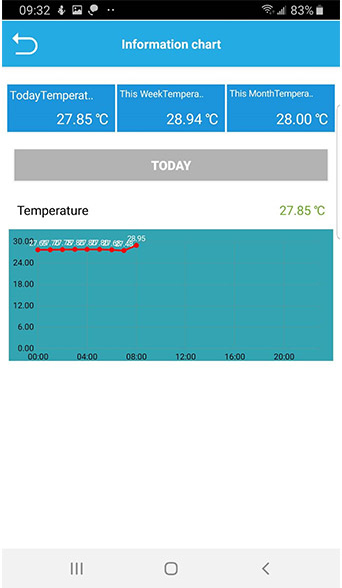

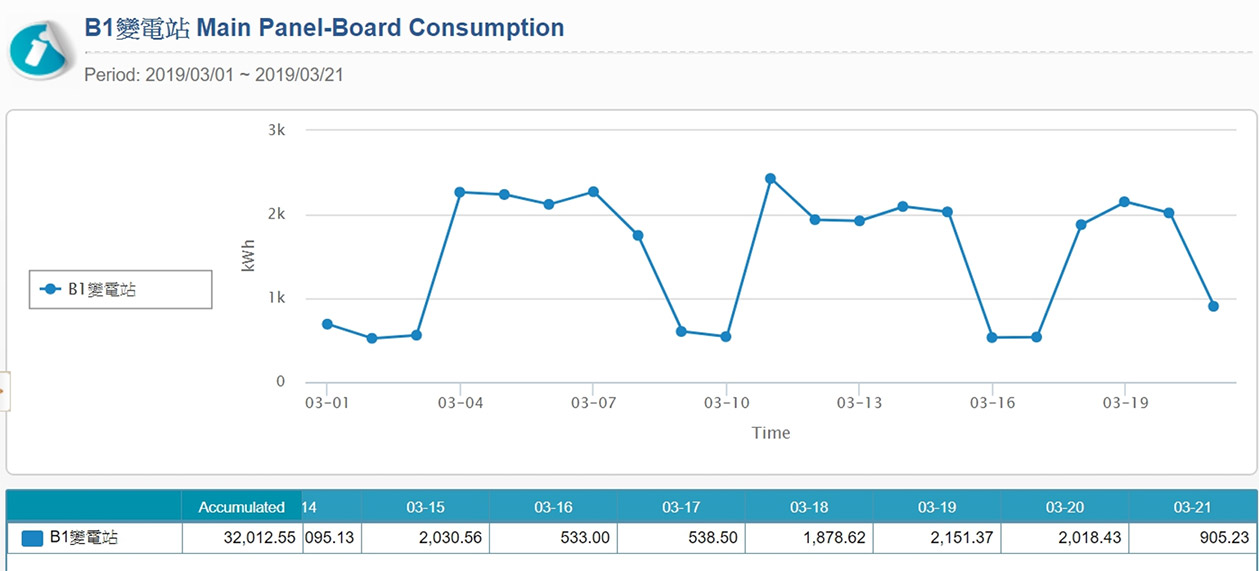

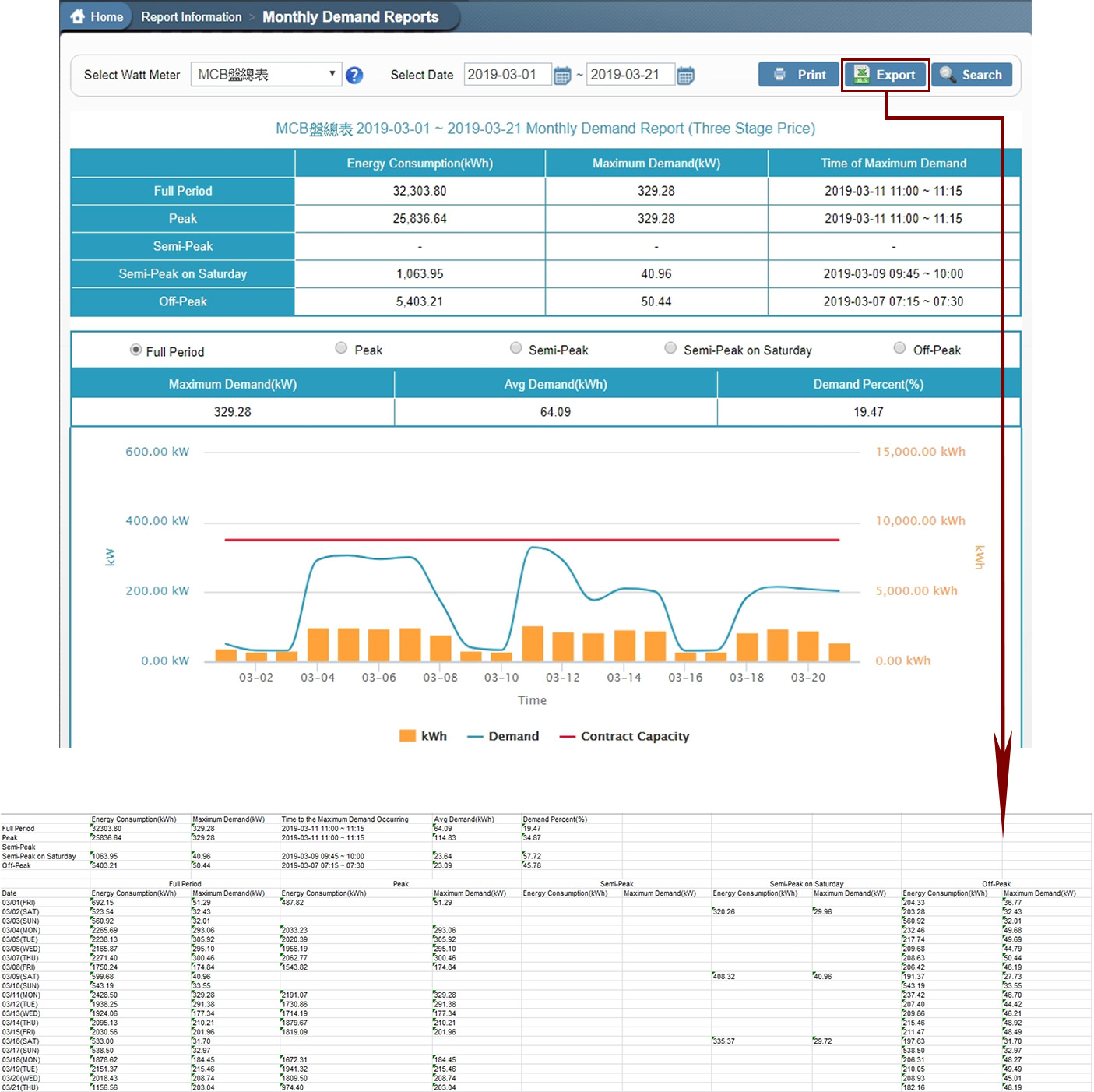

- Switchgear operation condition can be daily or monthly analyzed in the format of chart or report.

Maintenance

- Efficient regular maintenance can be planned with the statistics and analysis data which decreases maintenance cost.

Optimization

- Optimize energy consumption distribution on the basis of historical power parameter and distribute power stably to system.

Remote Control

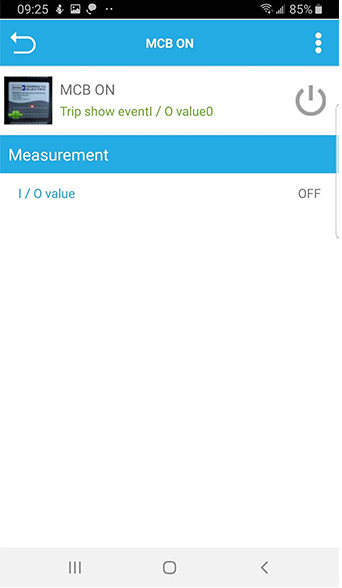

- In case of natural disasters and inevitable accidents, switchgear can set "Trip" by APP with authorized account.

Database

- Cloud system provides enterprises with an efficient and reliable platform for data storage and sharing which greatly influences modern business management.

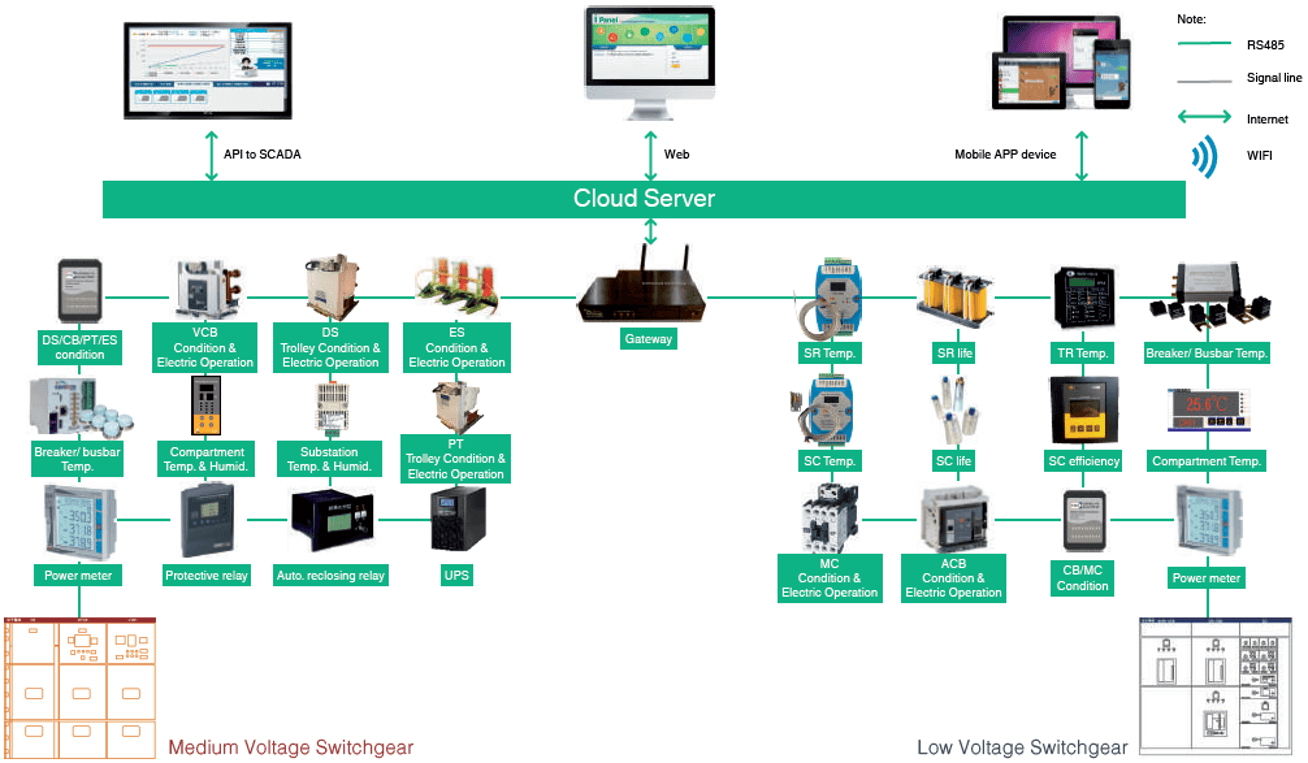

| Category | Item | Equipment monitoring |

|---|---|---|

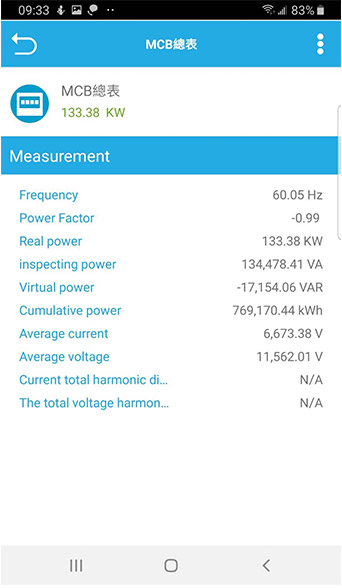

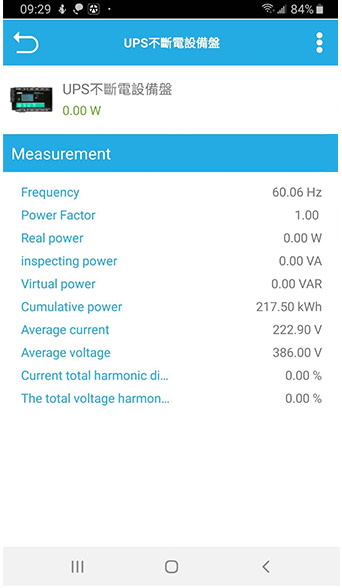

| Power value | Voltage, current, frequency | Power Meter |

| Real power(R), Apparent power(S), Reactive power(Q) | Power Meter | |

| KWH, KVARH, Demand | Power Meter | |

| Power factor, Voltage harmonic, Current harmonic | Power Meter | |

| Other power value | Power Meter | |

| Control value | CB operation & TRIP condition | DIO Controller |

| CB overcurrent message (50/51, 50N/51N) | Protective Relay | |

| CB fault voltage message (27/59) | Protective Relay | |

| CB reclosing message (79) | Auto. reclosing relay | |

| DS/ PT trolley/ Earthing switch condition | DIO Controller | |

| Other control value | Controller | |

| Safety value | Temp of CB contactor, cable connector, busbar joint point | Wireless Temp. and Humid. monitor device |

| Partial discharge value | Temp. and Humid. detector | |

| Temp. & Humid. of compartment | Temp. and Humid. detector | |

| Ambient Temp. & Humid. of substation | Galvanized Zinc Alloyed Steel (Front door painting SPHC) | |

| Capacitor Surface Temp. | Temp. detector | |

| Reactor Core Temp. | Temp. detector | |

| Transformer Core Temp. | 49 Relay | |

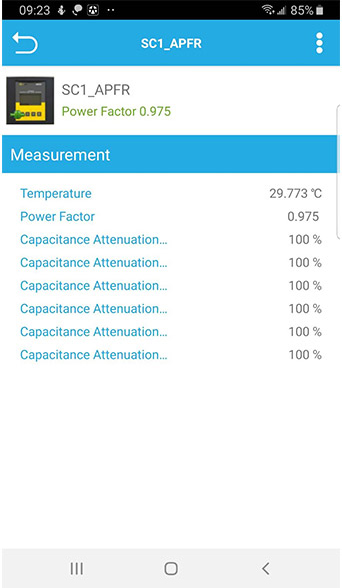

| Capacitor massage (degradation value, on-line capacity, closing time) | iAPFR | |

| UPS massage (battery capacity, remaining supply time) | UPS | |

| Other safety value | Sensor |

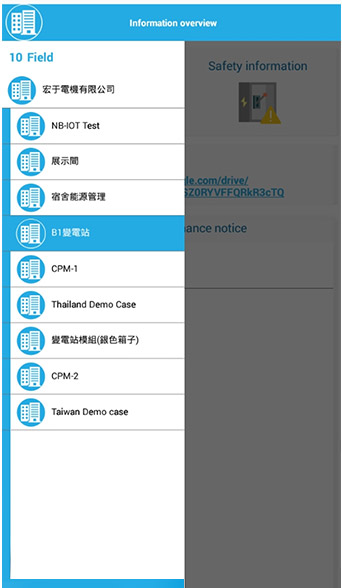

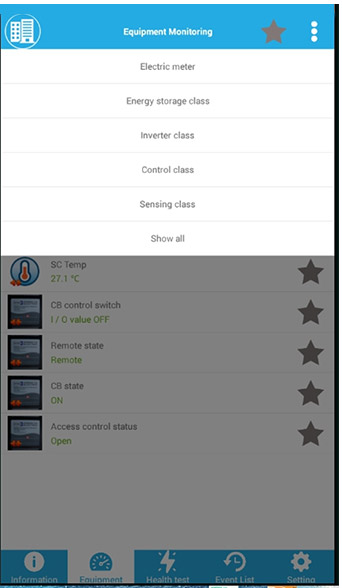

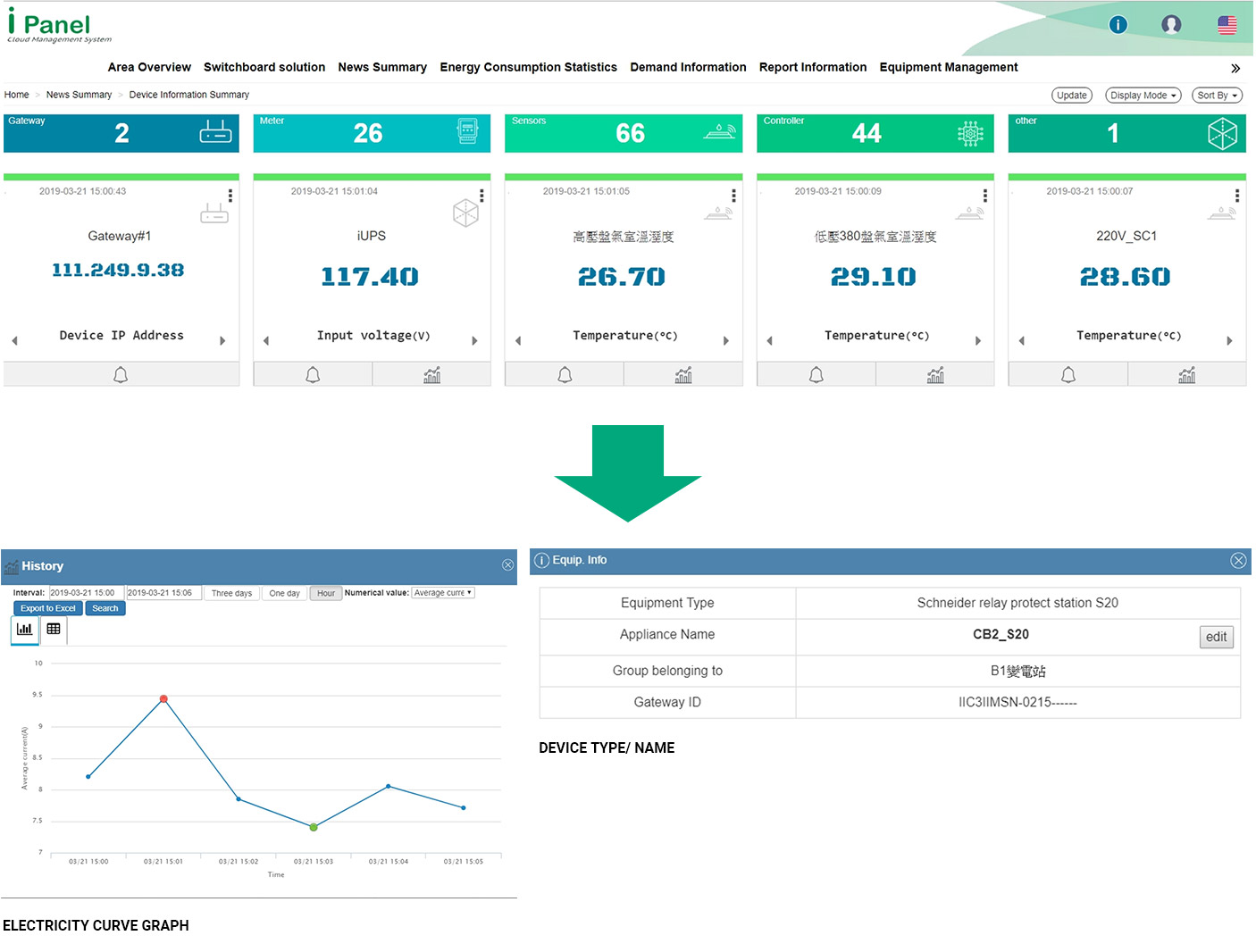

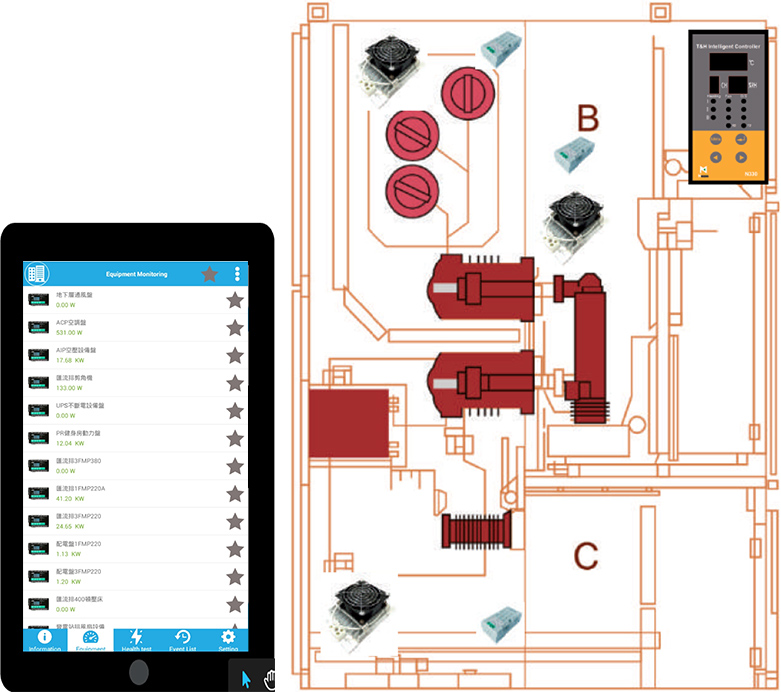

APP version

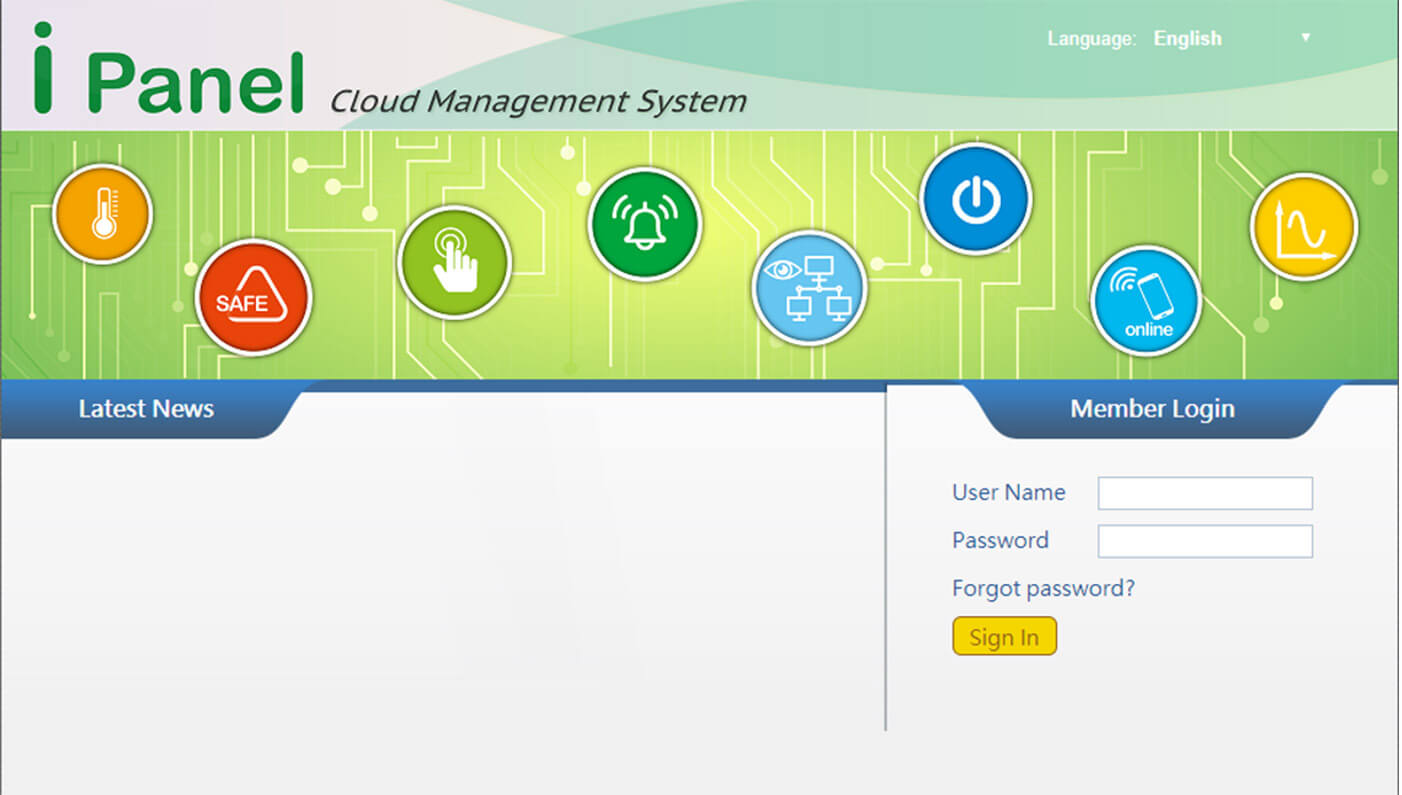

Website version

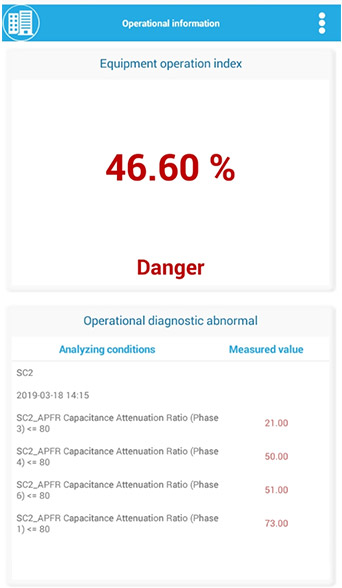

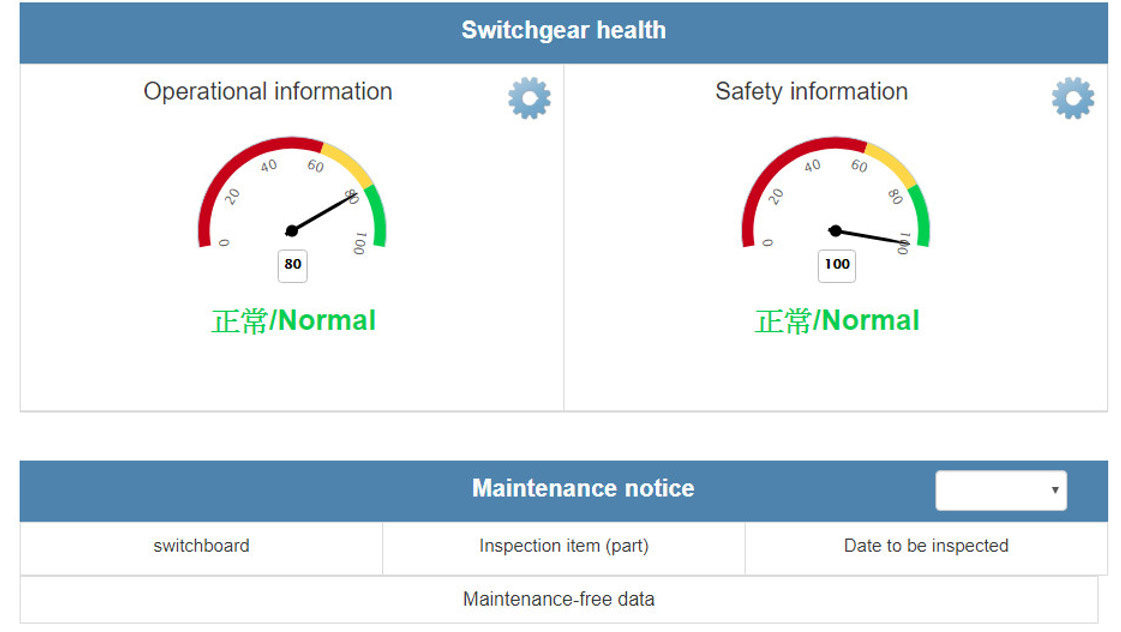

HEALTH BOARD of substation and switchgear operation

AI diagnosis Health indication:

- Green - Switchgear health is "Normal"

- Orange - Switchgear health is "Warning"

- Red - Switchgear health is "Abnormal"

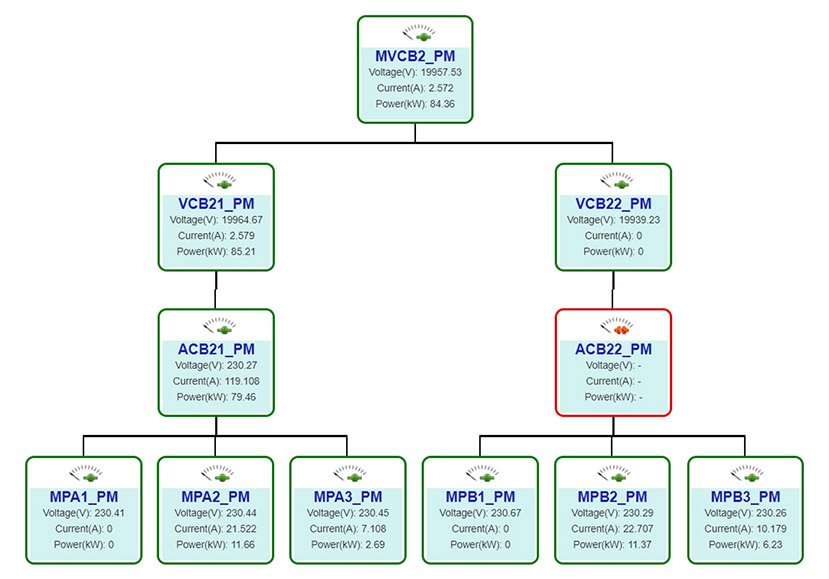

Substation and switchgear MANAGEMENT BOARD

- Green - All switchgears are in the online condition.

- Red - One of the switchgears is disconnected.

| Table of abnormal occurrence in this month | ||||

|---|---|---|---|---|

| Region | District | Unprocessed | Processed | Completed |

| Taiwan | Client A | 16 | 11 | 13 |

| Client B | 7 | 5 | 3 | |

| Vietnam | Client C | 10 | 5 | 2 |

| Thailand | Client D | 11 | 8 | 5 |

| Table of abnormal occurrence in this month | |||

|---|---|---|---|

| Region | District | Event alarm | Number of trip |

| Taiwan | Client A | 16 | 13 |

| Client B | 7 | 5 | |

| Vietnam | Client C | 10 | 5 |

| Thailand | Client D | 11 | 8 |

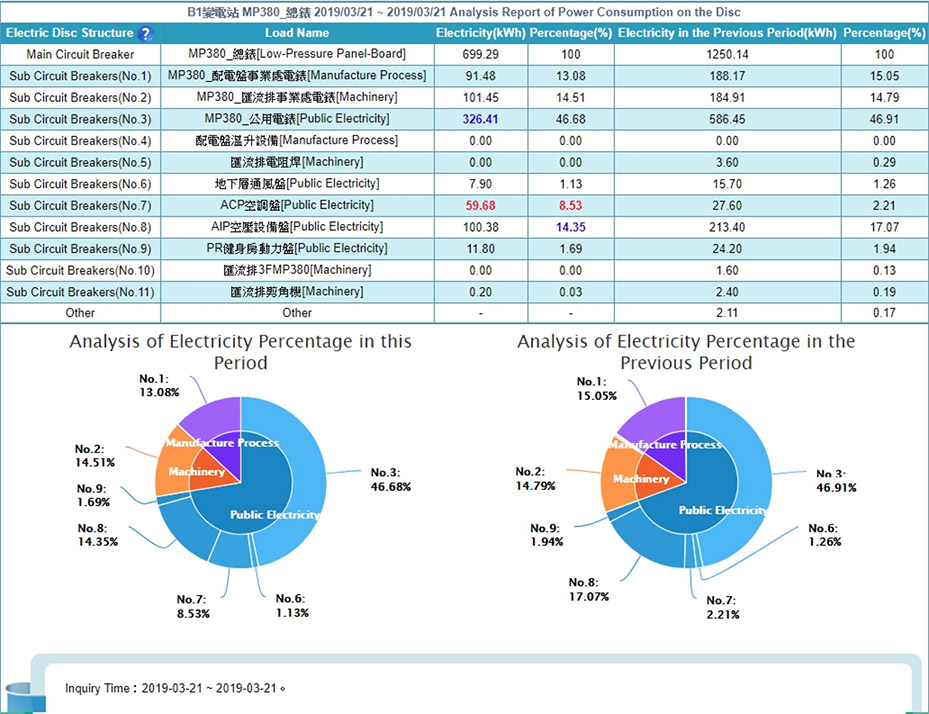

Demand analysis

Daily report subscription: Daily mails are delivered to client mailbox automatically.

Available to export Daily / Monthly / Yearly report with EXCEL report.

Current flow analysis

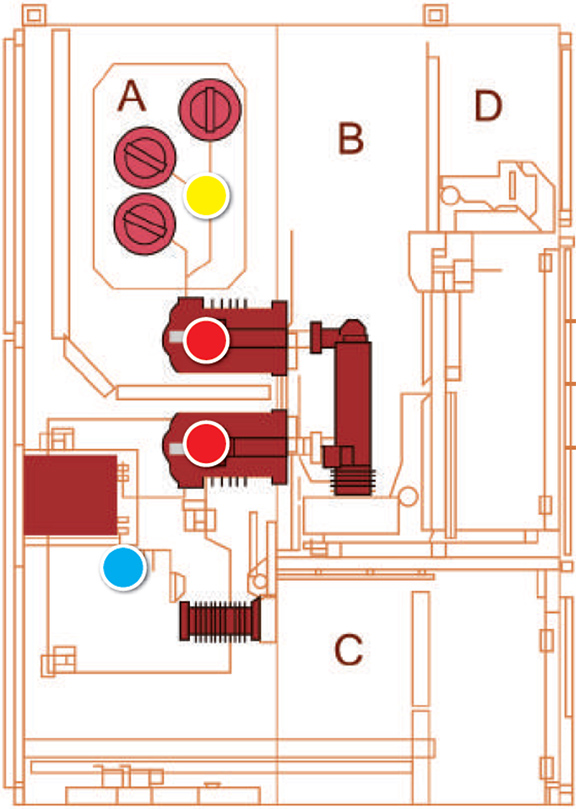

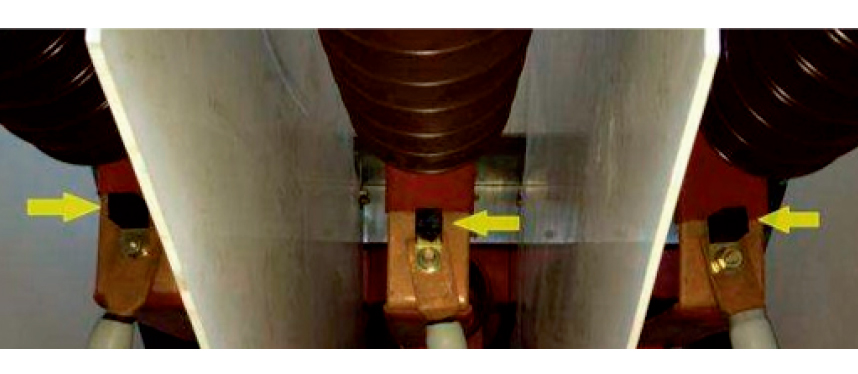

Switchgear Internal Temperature Rise THE COMMON PROBLEM IN SWITCHGEAR

Spots prone to temperature anomaly in medium voltage switchgear

Busbar

Load error interferes current consumption to nearly the upper safety limitation. Copper connection screw loosen makes contact resistance rise.

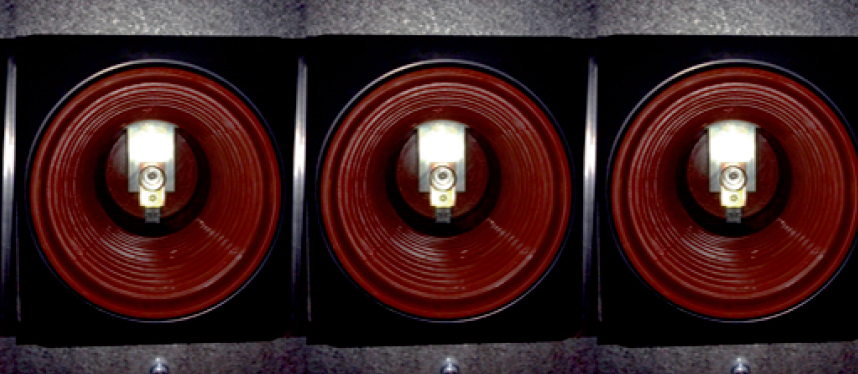

Circuit Breaker Joint

CB fixed and movable contactors are not connected completely that the over operation result in surface melting.

Cable Terminal

The raise of contact resistance, and insulation degrades results from loose of cable terminal.

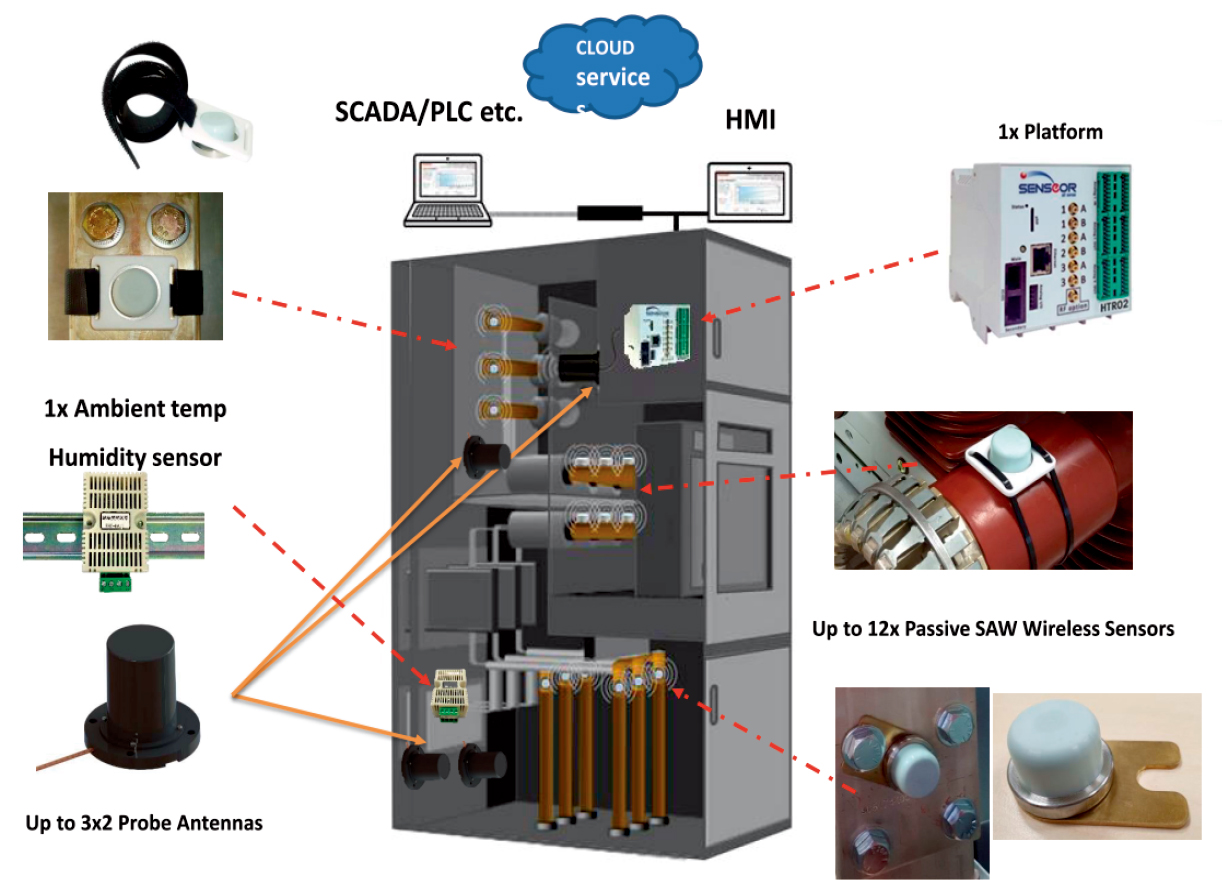

SOLUTIONTemperature and Humidity Online Monitoring

Wireless thermal monitoring

Wireless thermal monitoring device, composed of wireless sensors, antenna and reader adopts Surface Acoustic Wave (SAW) to sense temperature variation.

Indoor arrangement in the medium voltage switchgear, it features in continuous circuit breaker temperature online monitoring.

Battery-free

Adopting surface acoustic wave technique (SAW), self-powered by piezoelectric material.

Wireless transmission

Wireless reception and transmission with application of SAW.

Sensitive temp. sensing

Fast temperature measurement and free power consumption.

Insulating protection unrequired

Compact sensor which can be installed directly on medium voltage conductor.

Permanently maintenance-free

Battery-free sensor. Data reader is DC supply, no need to power off during replacement.

Partial discharge detecting

Ultra-high frequency (UHF) detecting function is used as an estimation of insulating degradation in the compartment, which enhances switchgear safety.

Ambient temperature & humidity of substation

Wireless thermal monitoring device, composed of wireless sensors, antenna and reader adopts Surface Acoustic Wave (SAW) to sense temperature variation. Indoor arrangement in the medium voltage switchgear, it features in continuous circuit breaker temperature online monitoring.

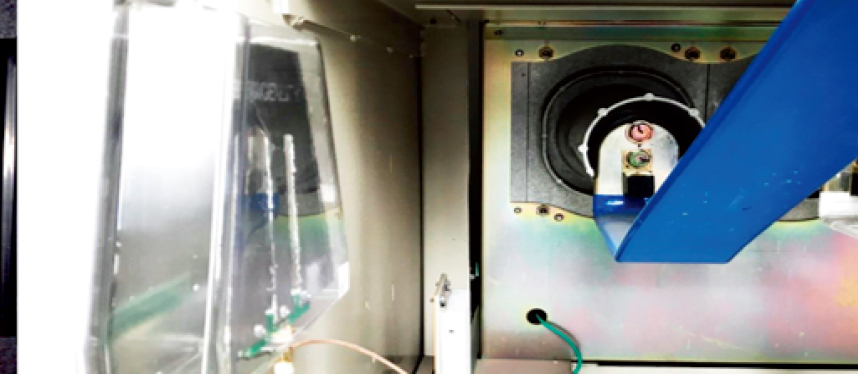

Temperature and Humidity Monitoring on switchgear compartment

(Standard IEC 62271-200) monitoring

Equipped with 3-circuit sensors which can monitor and control temperature and humidity of three compartments (CB room、Cable room、Busbar room) at the same time. Additionally, it can automatically heat up, dehumidify, and cool down inside of the switchgear to prevent accidents result from moisture, creepage, and flashover. Thus, safety in power system is increased.